Interactive CAD Solutions: Filling Holes and Beyond – with ANSYS SpaceClaim

“It wasn’t until I started modeling in SpaceClaim that I realized

what a good job it does. The more I used it, the more I liked it."

Robert Conley, Founder

Interactive CAD Solutions

Read More->

Soluma swiss AG: Delivering Better Customer Service – and Business Results – with SpaceClaim

“For us, SpaceClaim is a tool that supports us and enhances our service – before and after machining. We believe customers today want full-service support. For example, they want a knowledgeable partner who can also offer such quality features as traceability, document management, and ISO certification. SpaceClaim helps us become this kind of partner.”

Markus Wüst, CEO

Soluma swiss AG

Read More->

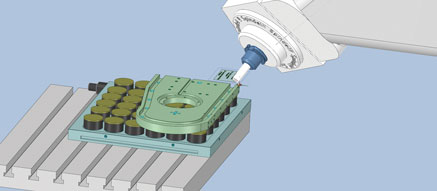

Hans Mattis GmbH: Efficient – Effective – CAD Data Processing for Contract Manufacturers

“SpaceClaim is extremely useful as a data hub for our customers’ various CAD input formats, and the integrated data preparation for our CAM system is particularly helpful.”

“SpaceClaim is extremely useful as a data hub for our customers’ various CAD input formats, and the integrated data preparation for our CAM system is particularly helpful.”

Arno Mattis, Managing Director

Hans Mattis GmbH

“The system never says never. We repeatedly get things we’ve never had before, and we keep finding new ways to achieve our goals.”

Raimondo Berger, Designer

Hans Mattis GmbH

Read More->

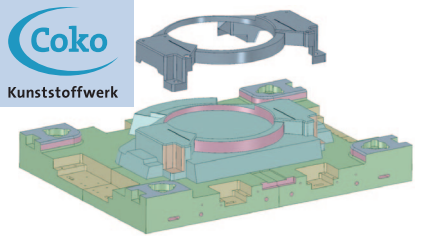

Coko Werk Streamlines Mold Manufacturing with SpaceClaim

"I was able to learn the basics of SpaceClaim in less than a day and with an intuitive interface the process to be productive was easy. SpaceClaim enables me to make the many changes I have to without going in and out of different software. It not only saves me time, it has made our workflow much less stressful.”

Frank Steinkamp, Designer

Coko Werk GmbH & Co.

Read More->

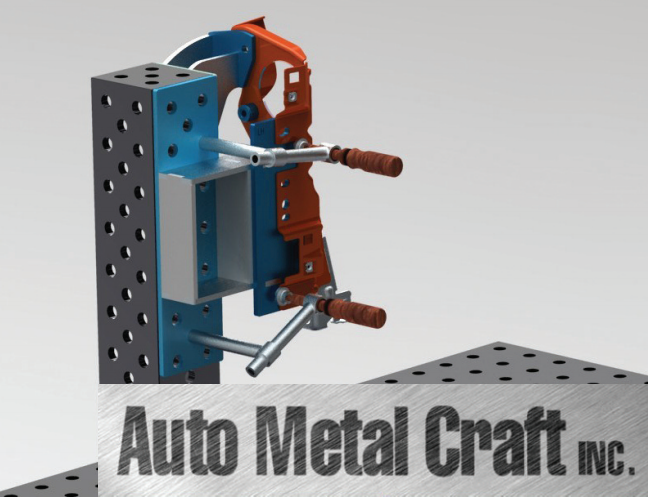

Auto Metal Craft Drives Automotive Parts Faster with SpaceClaim

“SpaceClaim is really a hands-on tool for us to make prototypes. Rather than being bogged down with CAD file conversions, we can work quickly, creatively and easily to ensure our customers receive designs that optimize their automotive or appliance products. With SpaceClaim, you just pull, move, fill and combine and you’re done...SpaceClaim is easy and flexible. The software does everything we need it to do. It’s so cost effective it’s almost too good to be true.”

“SpaceClaim is really a hands-on tool for us to make prototypes. Rather than being bogged down with CAD file conversions, we can work quickly, creatively and easily to ensure our customers receive designs that optimize their automotive or appliance products. With SpaceClaim, you just pull, move, fill and combine and you’re done...SpaceClaim is easy and flexible. The software does everything we need it to do. It’s so cost effective it’s almost too good to be true.”

Kevin Woody, Co-Owner

Auto Metal Craft

Read More ->

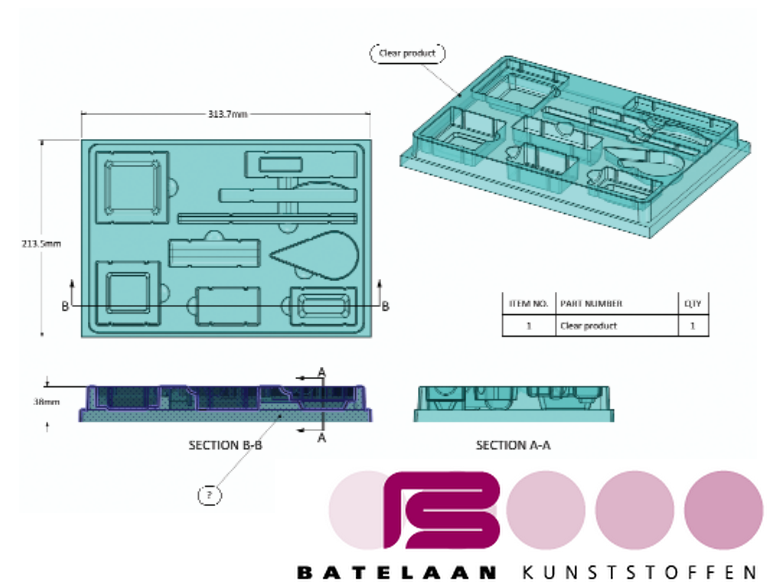

Batelaan Plastics uses SpaceClaim to Create Unique Products for Global Companies

"Manually recreating designs in our CAD system was a cumbersome process: it did not showcase our work well for prospects, and it took a lot of time. Now with SpaceClaim I have no limitations for design, our communications with customers are improved, and we've saved 60% to 70% of our time, enabling us to take on more business."

"Manually recreating designs in our CAD system was a cumbersome process: it did not showcase our work well for prospects, and it took a lot of time. Now with SpaceClaim I have no limitations for design, our communications with customers are improved, and we've saved 60% to 70% of our time, enabling us to take on more business."

Ed Swets, General Manager

Batelaan Plastics

Read More ->

Gunma Industrial Technology Center Introduces SpaceClaim as a Powerful Tool for Mold Flow Analysis

"Using SpaceClaim is so easy and intuitive that we have been able to quickly acquire it and apply it to many different research areas. As a result, we are now providing support not only for analysis preparation but also as part of the strategic research we perform in partnership with small- and medium-sized enterprises. SpaceClaim has extended our reach as well as enables us to research and develop new technologies and new products."

Hiroki Kuroiwa, Product Systems Researcher

Gunma Industrial Technology Center

Read More ->

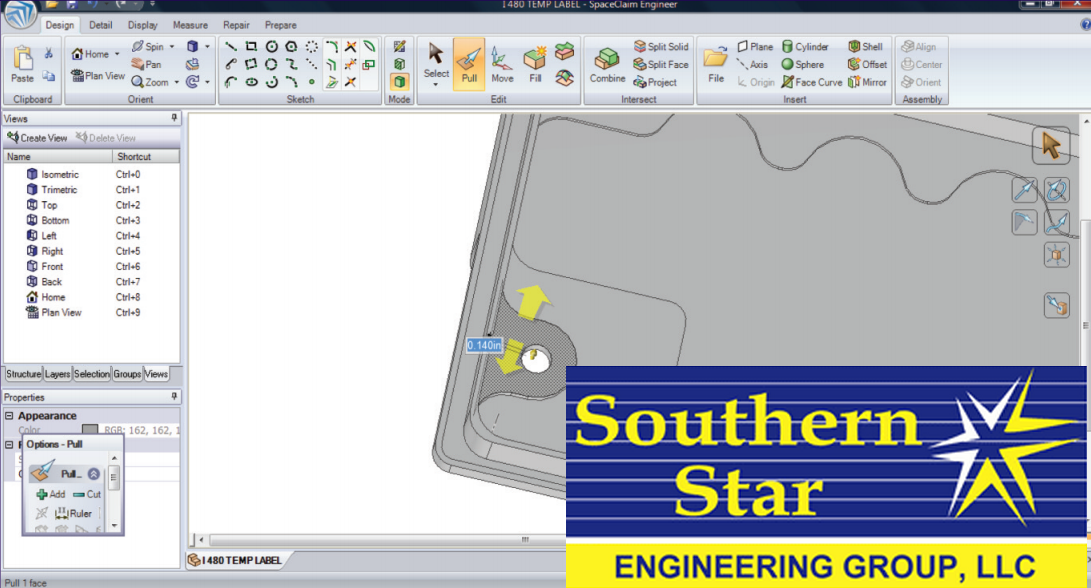

SpaceClaim Accelerates and Improves Processes for Southern Star Engineering Group

"Often, I am working with a plastics geometry that needs to fill a mold correctly. With SpaceClaim, I can now move the geometry into MoldFlow easily, find the mold filling issues, and, within minutes, correct the geometry in SpaceClaim."

Steven Taraglia, Founder

Southern Star Engineering Group

Read More ->

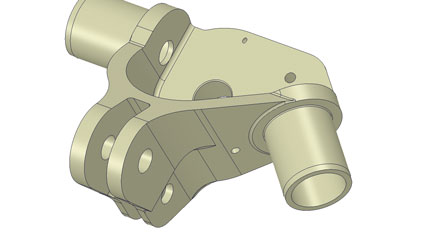

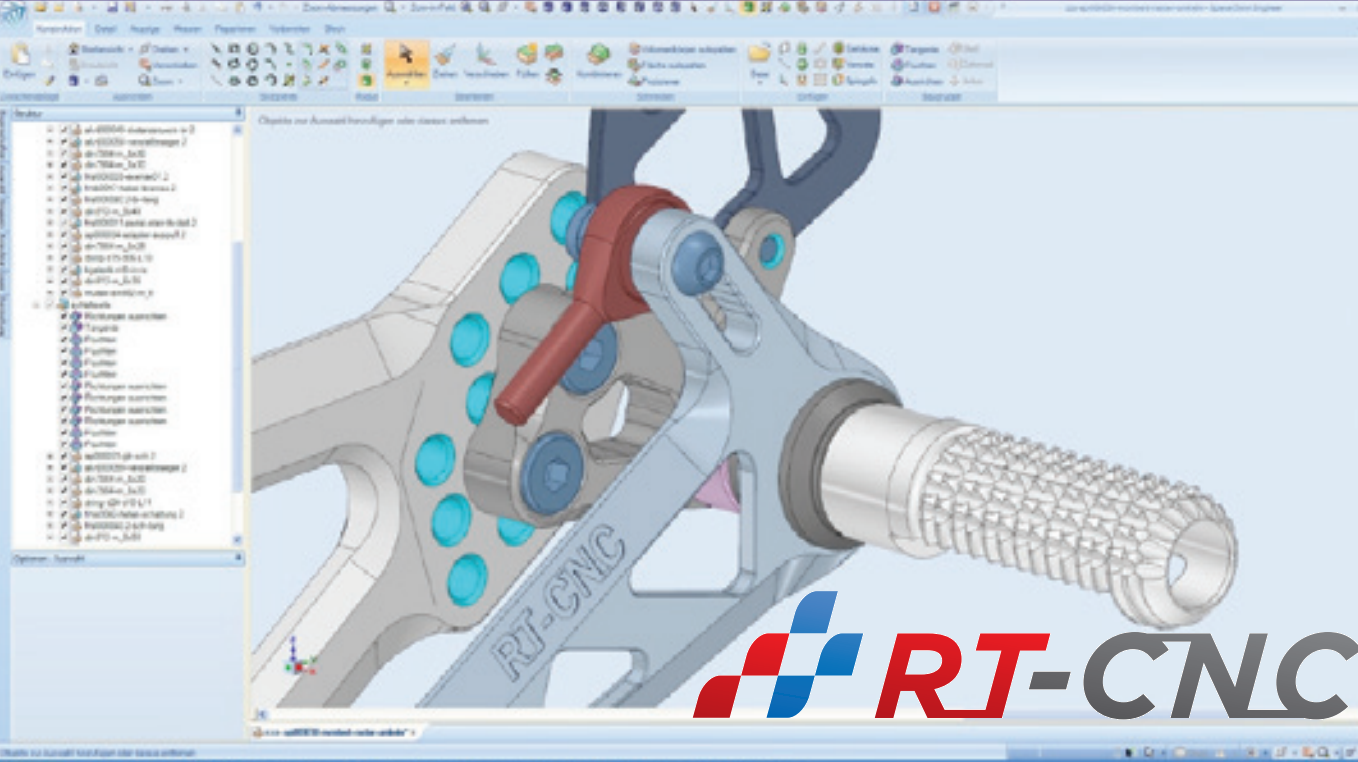

RT-CNC Develops Motor Sport Precision Parts with SpaceClaim

"This is the first 3D system with which I can work professionally and with minimum inconvenience. Its greatest advantage is its ease of use... What I can handle in SpaceClaim in five steps would have taken me 10 in a traditional system."

Raimondo Berger, Founder and Managing Director

RT-CNC

Read More ->

Seaway Plastics Simplifies Fixture and Jig Design with SpaceClaim

"My focus is taking a file from a customer that was sent in and using that file to build fixtures and jigwork. Hands down, it's been one of the best programs I've used. As far as ease and time savings SpaceClaim is the best, it's cut my time in half."

Rudy Colaizzi, Manufacturing Engineer

SeaWay Plastics

Watch More ->